Cemented carbide Nihon Hard Metal Co., Ltd.

Technical information

Development Capability

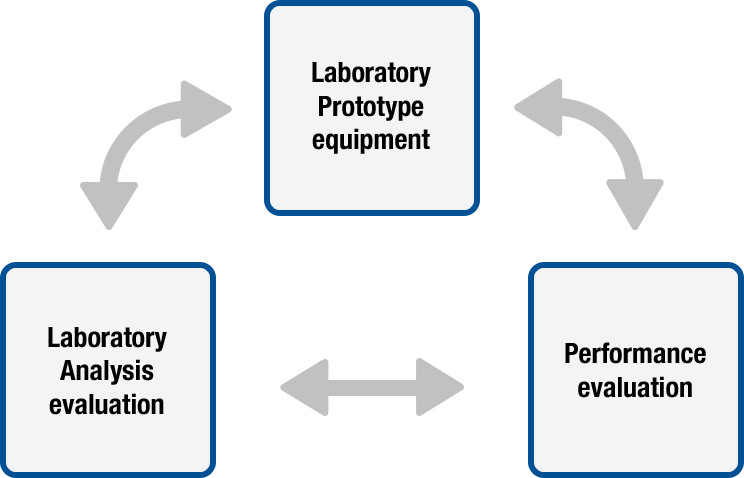

Nihon Hard Metal Co., Ltd. develops cemented carbide materials and processes by ourselves and also as part of industry - academia - government collaboration projects

Line of Business

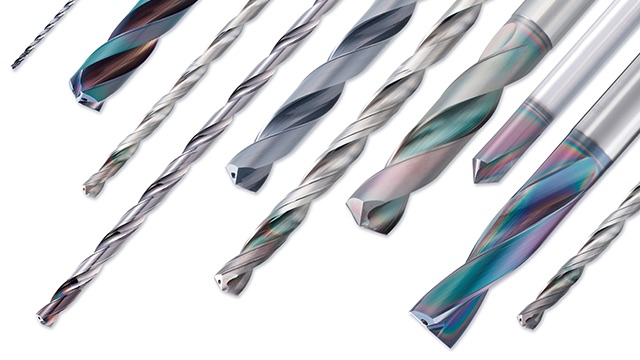

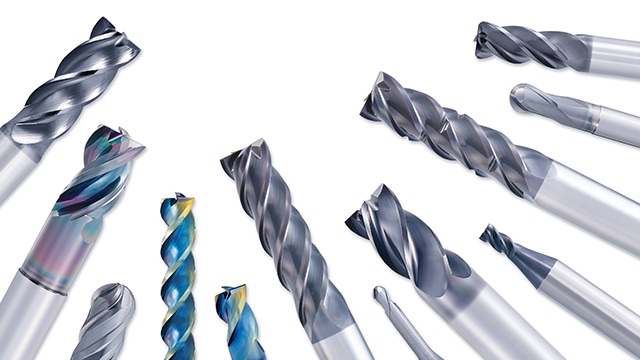

- ・Development of new materials for drills, endmills and taps

- ・Development of heat-resistant alloys

- ・Development of new binderless materials

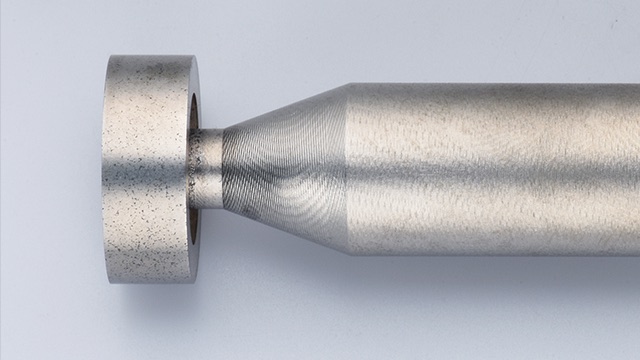

Product example

The materials we have developed can be used with a wide range of work materials and various tool configurations and are therefore used in the products of many tool manufacturers.

Equipment

Our main factory has a development laboratory provided with all the research equipment needed to enable quick development of new materials.

We also use a variety of analyzers and precision measuring instruments to accurately measure the physical properties of cemented carbides that are being developed.

SEM・EDX

SEM・EDX

- SEM・EDX

- We analyze powders of raw materials and mixed powders, observe them under high magnification and conduct other detailed assessments to improve material quality.

- Carbon analyzer

- A carbon analyzer measures the amount of carbon in the powder of raw materials or mixed powders as a means of quality control.

- Hardness measurements(Rockwell and Vickers)

- These testers measure the hardness of an alloy as a means of quality control.

- Saturation magnetization measurements

- Saturation magnetization is measured to determine the amount of carbon in the alloy, which is used as a means of quality control.

- Transverse rupture strength measurement

- A 3-point bend test is performed on alloys to measure their transverse rupture strength and that they are up to scratch.(Raw material lot check)

- 3D tester

- This tester measures the dimensional accuracy of an alloy to confirm there is no warping or deformation.

Nihon Hard Metal puts special emphasis on the development of new materials.

New binderless materials

Joint Research Akita Industrial Technology Center

Since the alloy does not contain any cobalt, it has better corrosion resistance and resistance to wear than existing cemented carbides.

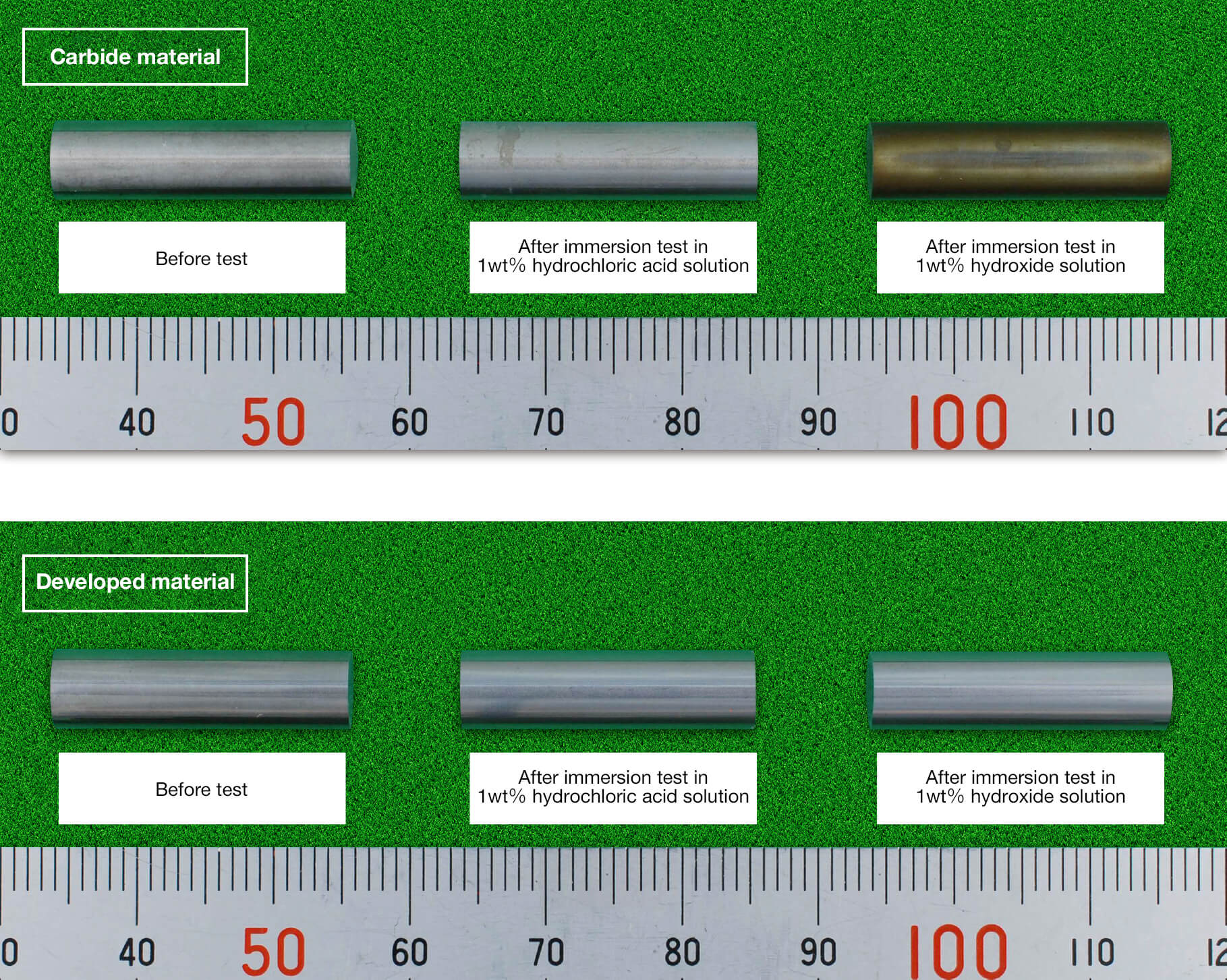

Result of comparison test after a 120-hour immersion in acidic and alkaline test liquids at room temperature

Mass measurement result after immersion test

| Test liquid | Test piece | Mass before test (g) | Mass after test (g) | Mass lost (mg) |

|---|---|---|---|---|

| 1wt% hydrochloric acid solution | Carbide material | 8.98358 | 8.97005 | 13.53 |

| Developed material | 7.93670 | 7.93662 | < 0.1 (0.08) |

|

| 1wt% sodium hydroxide solution | Carbide material | 8.98894 | 8.98846 | 0.48 |

| Developed material | 7.98526 | 7.98515 | 0.11 |

No corrosion was found in the new material after soaking it in the acidic solution.

Cemented carbides immersed in acidic or neutral solutions will leach cobalt and other metals from their surface.

This is referred to as the “rust” of cemented carbides.

New materials have greater corrosion resistance than cemented carbides.

The new material was harder and had better compressive strength than existing cemented carbides.

| New binderless materials | Cemented carbide | Iron S45C(Quenched and tempered) | |

|---|---|---|---|

| Hardness (HV) | 2100-2200 | 1650 | 212~284 |

| Compressive strength (MPa) | 6400 | 4600 | 690 or higher *tensile strength |

| Transverse rupture strength (MPa) | 1500 | 4300 | - |

Since the material does not contain any cobalt, which is ferromagnetic, it is not attracted to magnets.

New materials are not only used in automobiles, electronic devices or airplanes, but in a wide variety of devices.

- Parts that are continuously exposed to heavy loads

- Parts that need to be wear resistant

- Parts operating in strong acidic or other harsh environments

- Parts that need to be corrosion resistant

- Parts that need to be heat resistant

New binderless materials can be used for the above parts. (Rod materials can be processed)

Since these binderless materials have size and other constraints, customers should be sure to consult us before making a purchase.