Cemented carbide Nihon Hard Metal Co., Ltd.

Technical information

What is Cemented Carbide?

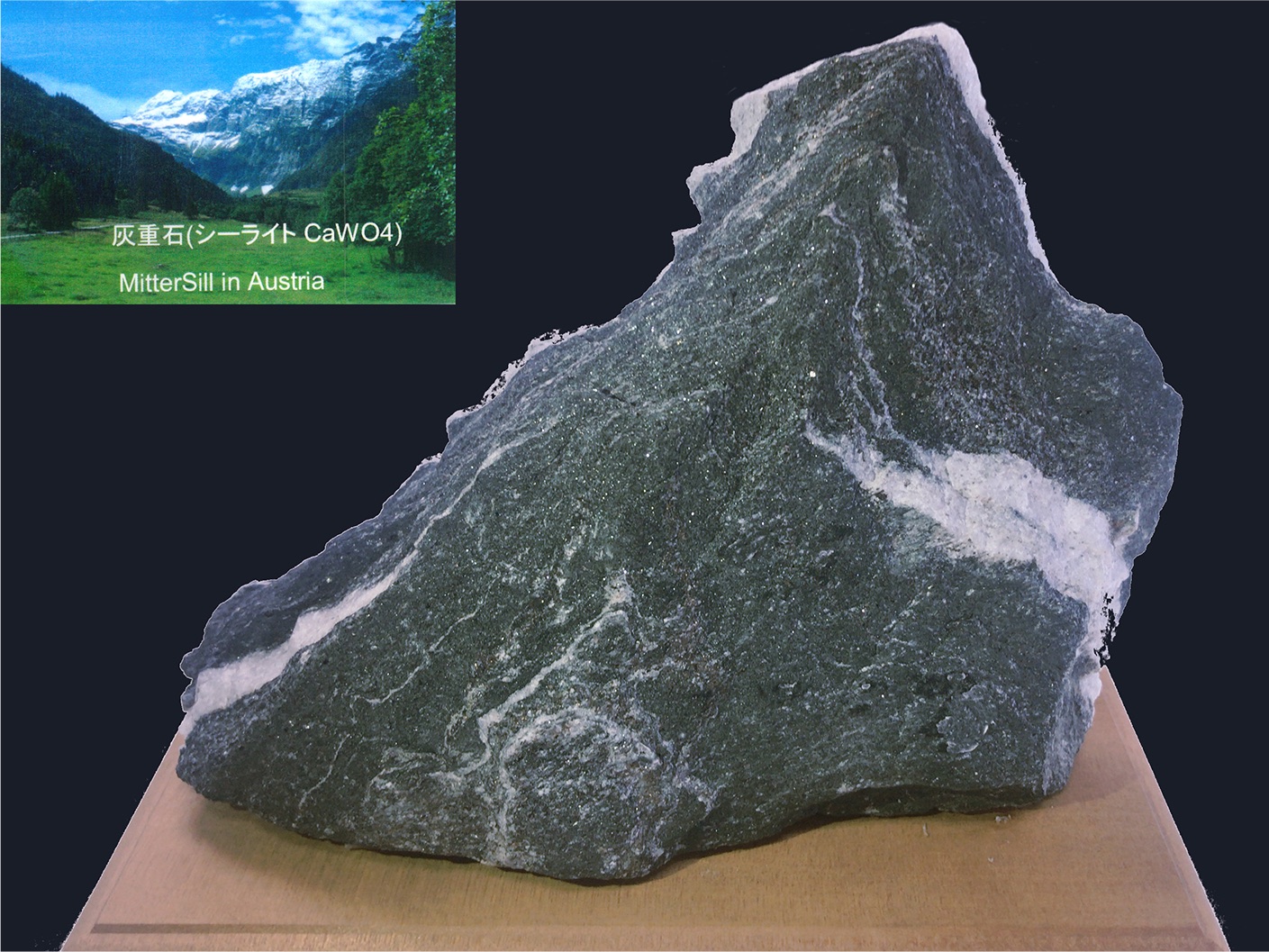

(Scheelite)

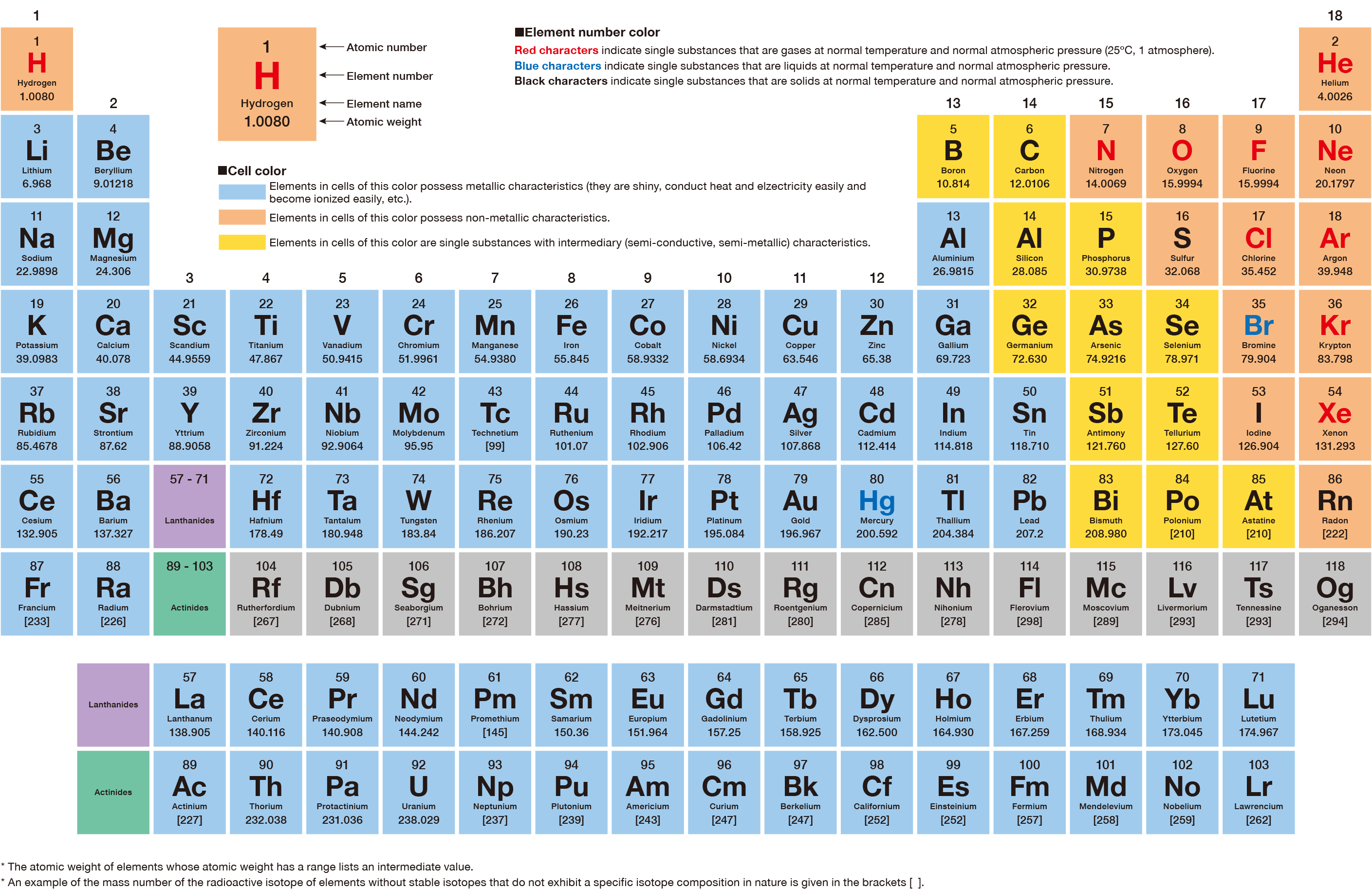

Cemented carbide refers to nine types of metal carbides belonging to Group IVa, Va and VIa in the periodic table. In powdered form, the carbides are combined with ferrous metals such as iron, cobalt or nickel and sintered to form an alloy.

Periodic table of elements

(Click the image to open the PDF)

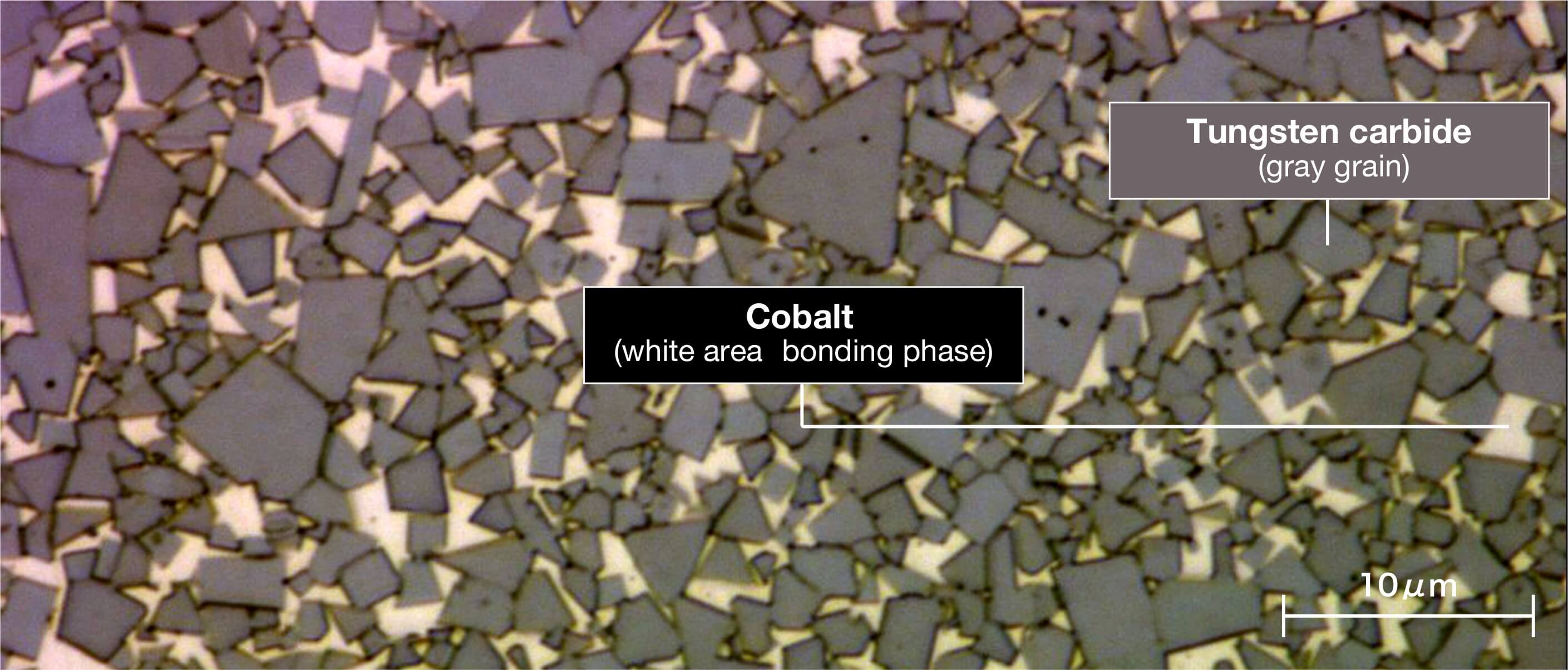

Nihon Hard Metal Co., Ltd. uses powder metallurgy to bond tungsten carbide (WC), the main component, with cobalt (Co), as the binding material, to form cemented carbide.

WC-Co cemented carbides have long been used in cutting tools.

Tungsten is a hard material with high heat conductivity. Therefore the cutting edge of a tungsten tool is resistant to wear and its temperature does not rise significantly making it an ideal base material for tool manufacture.

Tungsten carbide powder

Cobalt powder

Photo showing the structure of cemented carbide

To leverage the capacity of a cutting tool, it is essential to select the right base material depending on the material to be cut and the cutting conditions.

The table below compares the characteristics of cemented carbide with other hard materials.

List of room temperature characteristics of various hard materials

| Sintered high-speed steel | Cemented carbide | Cermet | Ceramics (Al2O3ceramics) |

Sintered diamond | ||

|---|---|---|---|---|---|---|

| Hardness | Knoop hardness or Vickers | 750〜940 | 1200〜1800 | 1300〜1800 | 1800〜2100 | 6000〜8000 |

| Transverse rupture strength | GPa | 2.5〜4.2 | 1.0〜4.0 | 1.0〜3.2 | 0.4〜0.9 | 1.3〜2.2 |

| Compressive strength | GPa | 2.2〜3.6 | 3.0〜6.0 | 4.0〜5.0 | 3.0〜5.0 | 6.9 |

| Fracture toughness | MPa・m1/2 | 12〜19 | 8〜20 | 8〜10 | 3〜4 | - |

| Degree of elasticity | GPa | 210〜220 | 460〜670 | 420〜430 | 300〜400 | 560 |

| Coefficient of thermal expansion | /K | 9〜12×10-6 | 5〜6×10-6 | 4〜5×10-6 | 7.8×10-6 | 5.9×10-6 |

| Heat conductivity | W/mK | 17〜31 | 20〜80 | 8〜12 | 17〜21 | 100 |

| Maximum operating temperature | K | 〜800 | 〜1300 | 〜1400 | 〜2000 | 900〜1600 |

Cemented carbide characteristics

- Very hard and remains stable at high temperature

- Cemented carbide has about the same hardness as ceramics and cermet, but is much tougher.

- Compressive strength and degree of elasticity is high(Highest of all tool materials)

- Coefficient of thermal expansion is small(1/2 of copper)

- Heat conductivity is high

- Tensile strength is small

- High corrosion resistance when exposed to air