Cemented carbide Nihon Hard Metal Co., Ltd.

Product information

Twisted coolant hole rod

Rod material with 2 holes, spiral oil holes, rod material with 3 holes, spiral oil holes

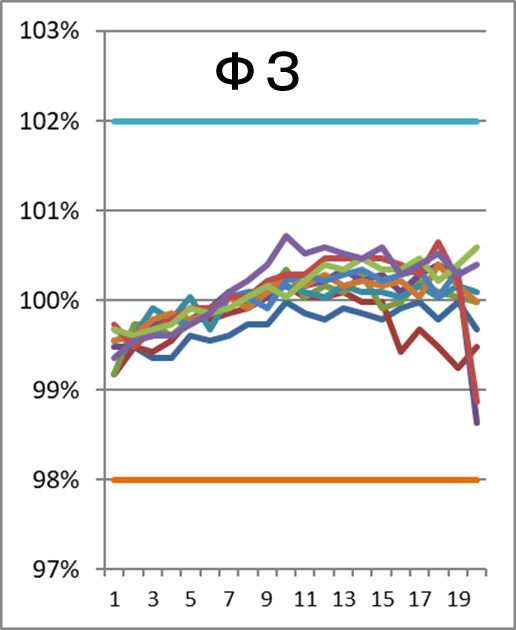

The material with oil holes for cooling requires a hole that must be precisely located and whose helix angle must be precisely determined to prevent hole breakdown during groove processing. The variations in manufacture of the helix angle and lead precision of our twisted hole material are very low and the material enjoys a reputation for world-class quality.

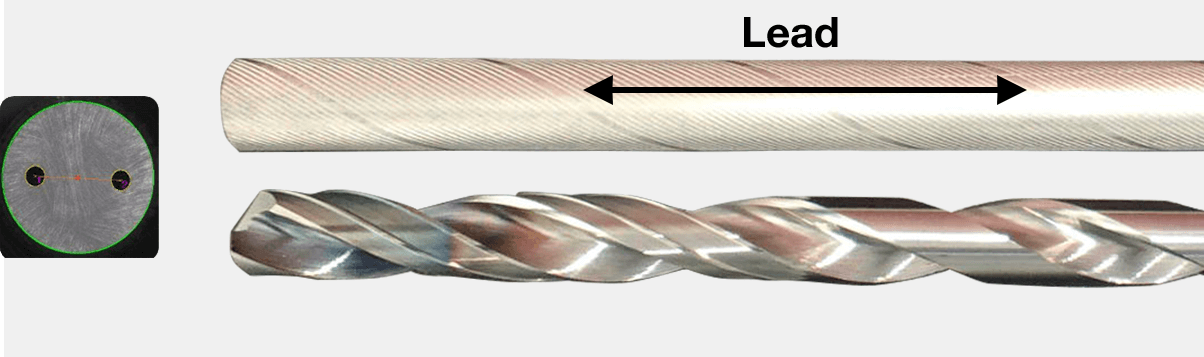

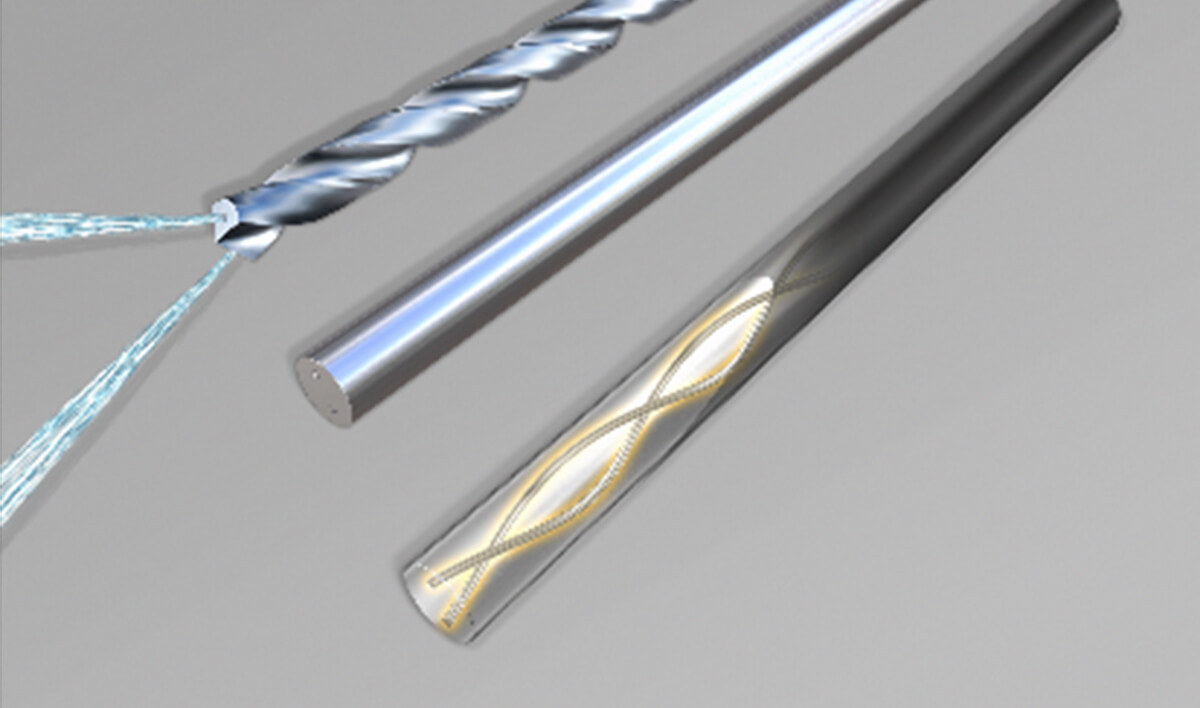

Some drills contain oil holes that follow the twisted groove of the drill.

Coolant is run through the inside of the drill to cool it during processing.

The oil holes in the twisted hole material of the drill are spirally formed to follow the shape of the groove in the drill.

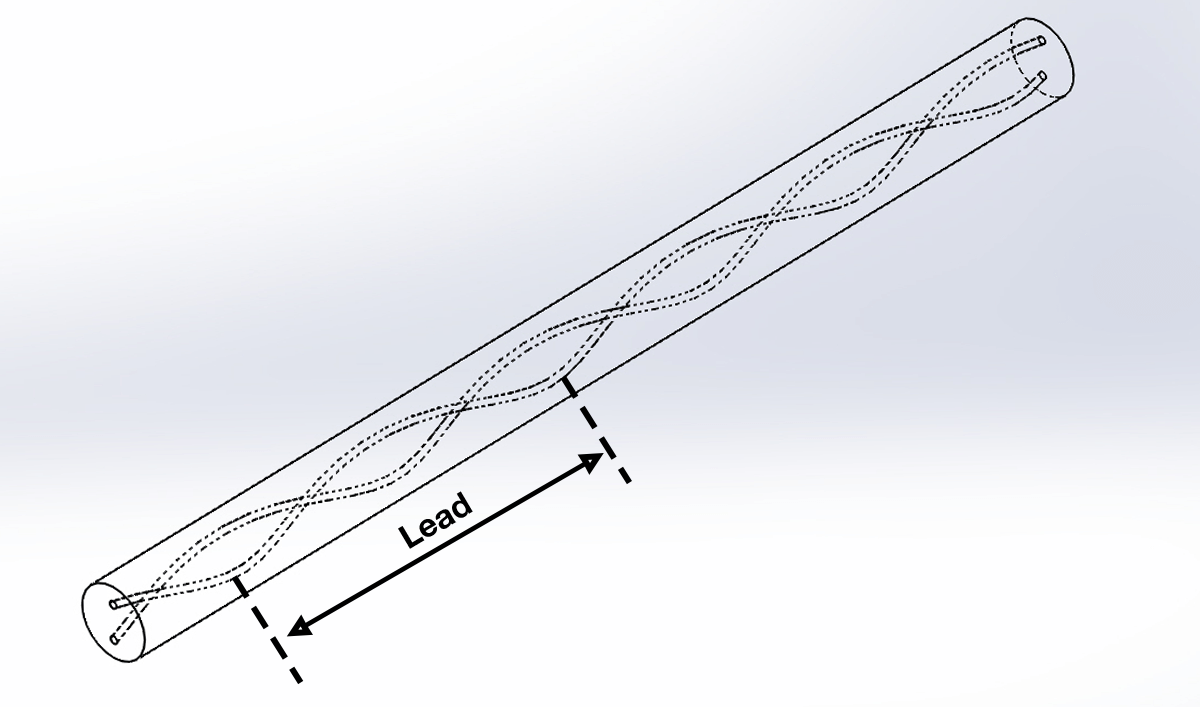

The position of the oil hole and its helix angle must be precisely determined. There must be no machining variations in the distance traveled in the axial direction (called the lead) as it circles around the axis along the leading edge of the cutting tool.

If these are not sufficiently accurate, the oil holes will be exposed when the groove of the drill is formed.

The machining variations in the helix angle and lead precision in the manufacture of the Nihon Hard Metal twisted hole material with 2 holes are very low and enjoys a reputation for world-class quality.

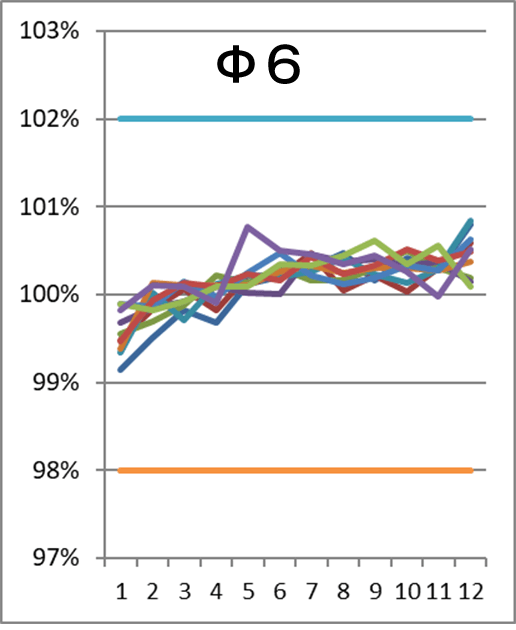

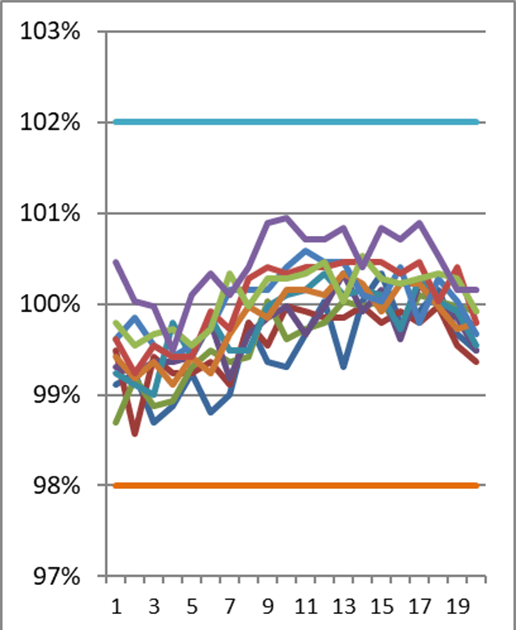

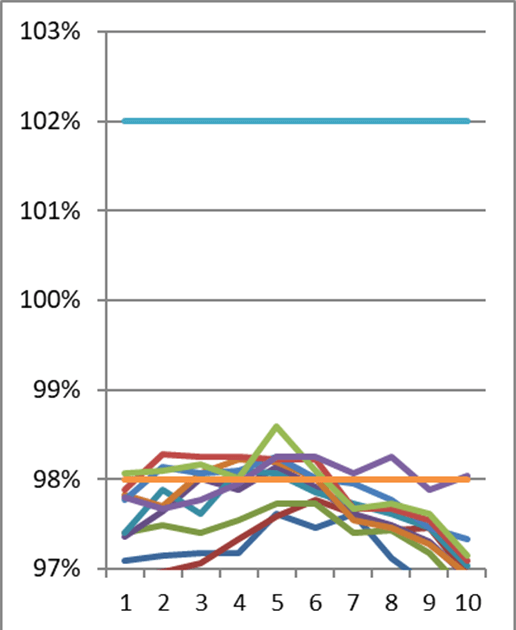

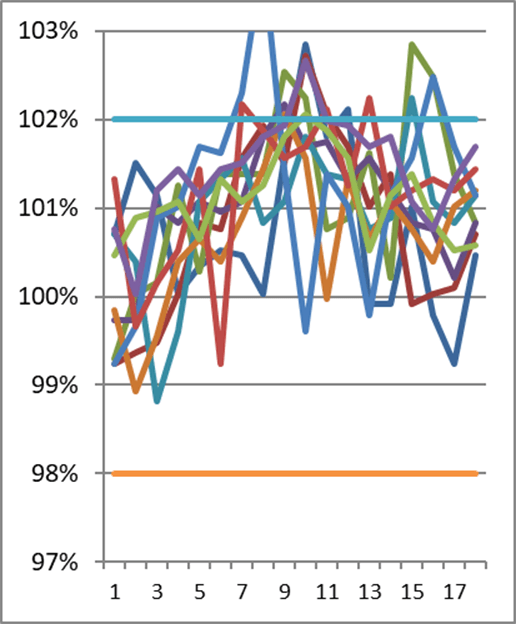

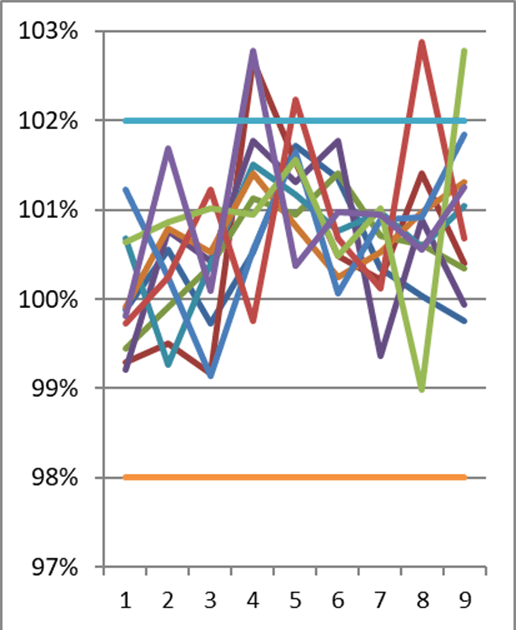

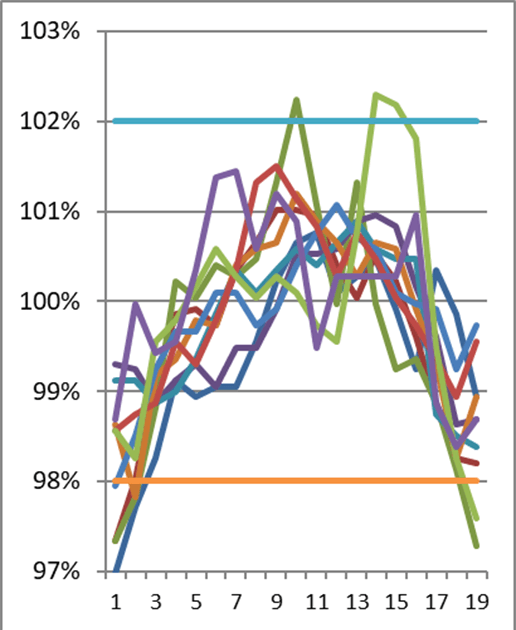

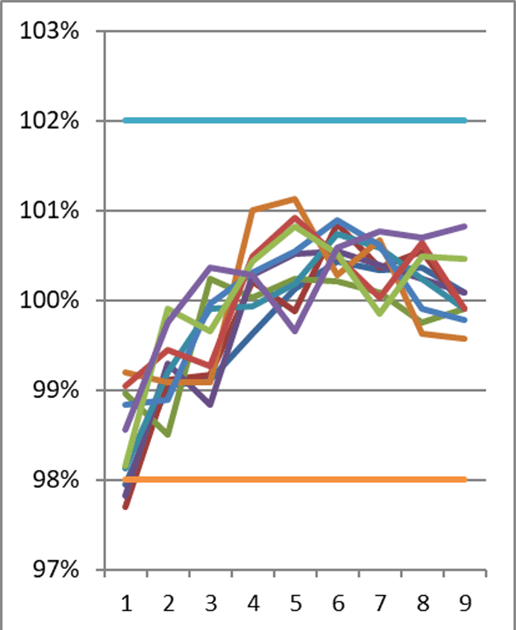

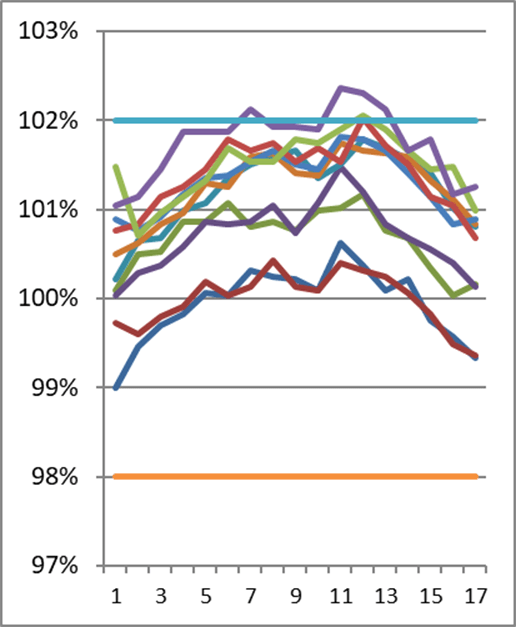

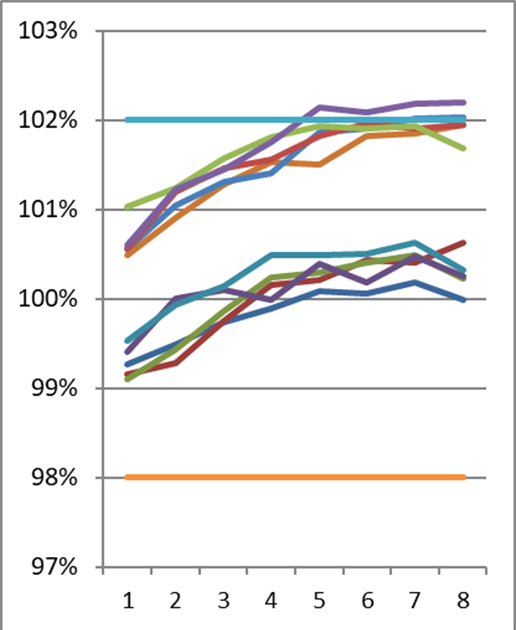

Comparing the lead accuracy of twisted hole material with two twisted holes from other companies

Nihon Hard Metal

Co., Ltd.

Company A

(overseas)

Company B

(overseas)

Company C

(overseas)

Company D

(Japan)

We also have a patent on how to recognize this lead.(Patent No. 3932529)

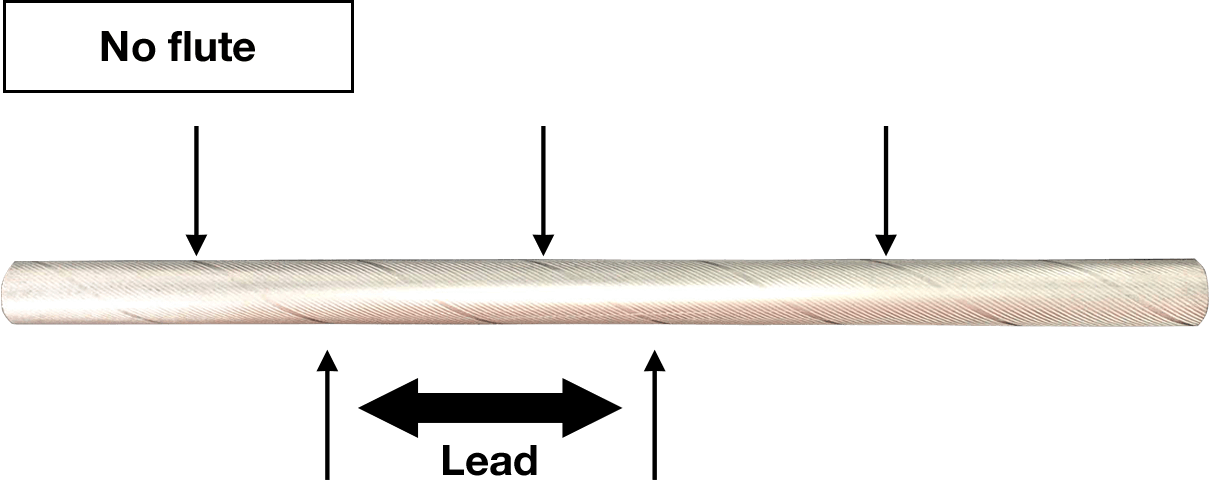

There are fine grooves on the entire surface of the rod material, but you can visually check the lead spacing by eliminating one of them.

This also helps improve the efficiency of processing grooves.